徹底した品質管理と基本作業の教育を行う中で信頼・安定の製品を構築します。

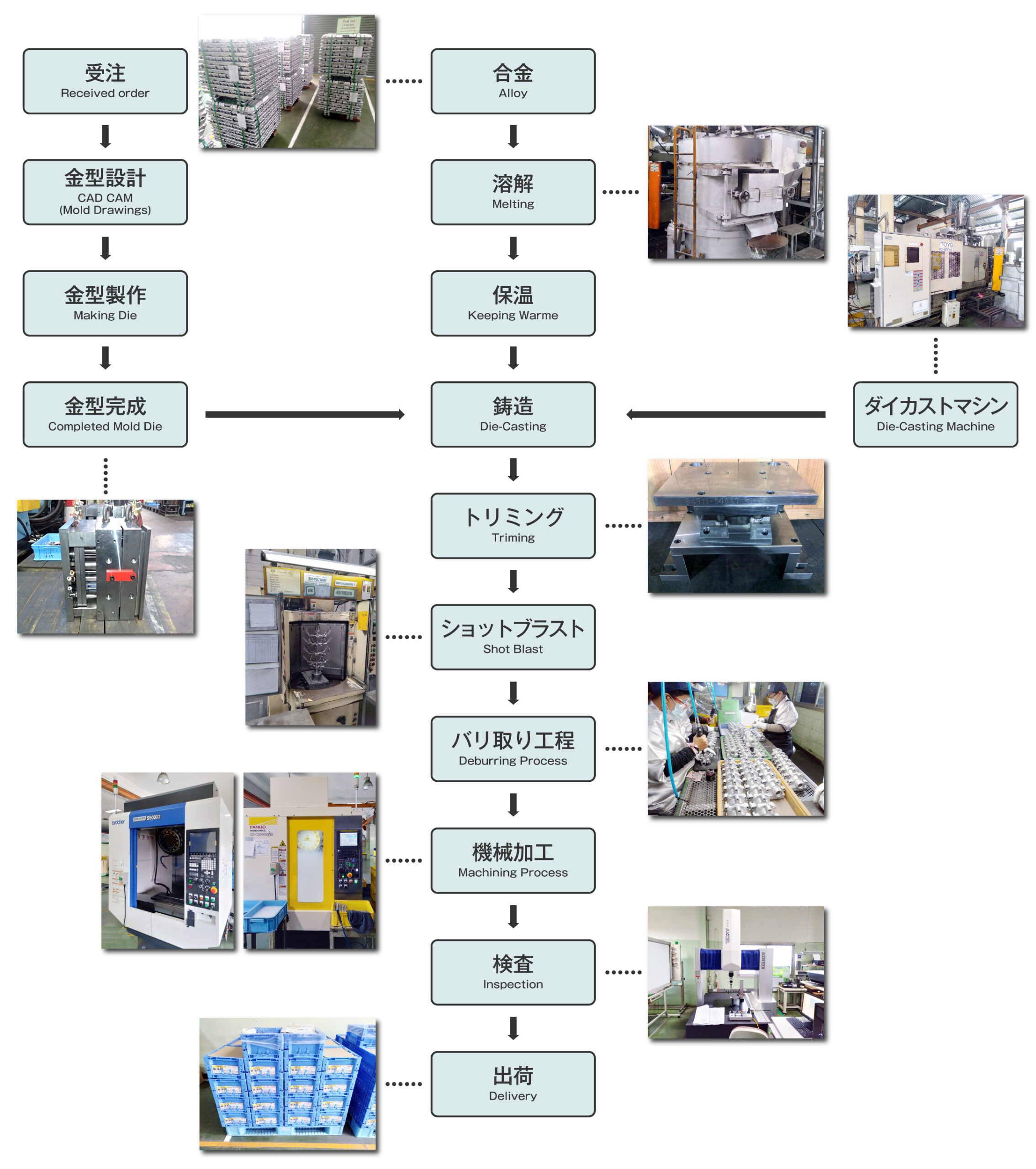

製造工程は、素材検査→溶解→鋳造→二次加工→全数検査の主要工程順に進めます。

素材及び溶解材検査は、常時成分分析を行い、把握管理する中で工程内での製品のトレサビリティを構築しています。

まず鋳造工程では、素材を温度管理された中で溶解し金型に流し込み、形成、トリミング後に二次加工を行い全数検査及び出荷検査に合格した製品のみ、梱包されお客様への出荷となります。

鋳造から加工・検査までお客様に合わせた品質管理のもと製造をいたします。

We construct the products with trust and stability while educating our employees in thorough quality control standards and basic operations.

Our production process follows the main process order of material inspection-melting-Die casting-elaboration-100% inspection.

Within each of these processes,we accomplish traceability of our products, while monitoring our product management,

by continually performing component inspections of both raw materials and molten alloys.

In the Die-casting process, first, raw materials is melted by controlled temperature and poured into mold and formed.

After trimming, the products are elaborated, and only products that pass both a 100 % inspection and delivery

inspection are packaged and delivered.

From Die-casting to processing and inspection, our manufacturin g process is performed according to quality control

standards tailored to meet our customer’s needs.